Field report from KITO user company Bharat Forge CDP GmbH in cooperation with KITO sales partner Kranservice Essers

Bharat Forge CDP GmbH is a customer of our sales partner Kranservice Essers GmbH and uses KITO products in their applications. Established in the crane industry for more than 30 years, Bharat Forge CDP has been part of the Indian Kalyani Group – one of the leading industrial companies in India – since 2004 and is a leading supplier of forged chassis and engine components as well as non-automotive systems. More than 20 years of experience and technology know-how in the globally oriented supplier and forging landscape distinguish the company. They offer innovative lightweight solutions using appropriate materials and optimised component design, ensuring a strong and successful presence in various segments. Bharat Forge CDP is active in the application areas of chassis, powertrain, and railway technology. Customer satisfaction is the top priority. KITO was in Ennepetal, where Bharat Forge CDP GmbH is located, and met the Head of Maintenance Infrastructure Mr Höh and the Managing Director of Kranservice Essers GmbH. Bharat Forge CDP GmbH has been working with Kranservice Essers GmbH for about five years. Installations and repairs of crane systems are the main activities. For Mr Höh, who is in charge of the entire maintenance infrastructure and also responsible for crane systems and hoists, Kito Europe GmbH was completely unknown. “Until now, the hoists were almost exclusively installed by Demag. I became aware of Kito Europe GmbH through Mr Essers. Mr Essers described KITO’s hoists as very robust and powerful.” Contact was then made with KITO’s field representative, Mr Klar, and a joint appointment was arranged with the KITO DemoVan at the beginning of 2020. The DemoVan is equipped with the most important hoists from the KITO product portfolio. From the lever hoist or ratchet hoist to the manual chain hoist and the electric chain hoist, it has everything that the industry requires. The advantage of this vehicle is that it is possible to convince oneself of the product characteristics on site and to test all hoists. After answering the questions and discussing the requirements, Mr Höh ordered a KITO ER2 Electric Chain Hoist with a load capacity of 500 kg.

The KITO ER2 Electric Chain Hoist is an all-rounder and is particularly suitable for the toughest conditions. High performance, durability and robustness are not foreign words to him. Like all KITO products, the ER2 Electric Chain Hoist are designed for long-lasting use. The chain hoists remain corrosion-resistant due to their aluminium housing (diecast) and powder coating, and the internal components (including electromagnetic brake, gearbox, high-quality frequency inverter and friction clutch made of carbon) are designed and well-supported for rough conditions. Last but not least, the electroless nickel-plated load chain, securely placed in the steel chain container, guarantees a continuous flow. The KITO load chain is more resistant than conventional load chains. KITO is the only manufacturer in the world that nickel-plates its load chain electrolessly. The symbiosis of hoist and chain ensures the best possible safety, durability and efficiency. The high-quality load chain is characterised by effective prevention of hydrogen embrittlement, corrosion resistance and a special surface hardness. For Bharat Forge CDP, this means less wear, longer service life and durability, lower maintenance costs, lower costs due to the longer service life and higher safety.

“So far, the units have been running absolutely trouble-free. That can only be praised.”

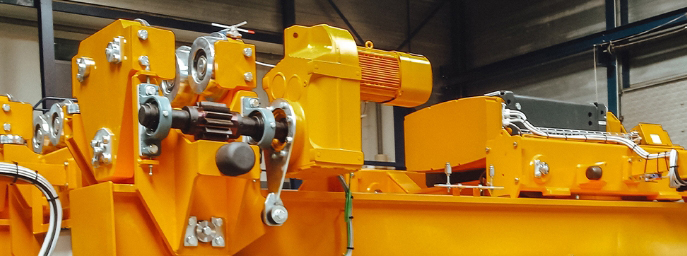

Mr Höh was convinced by Mr Essers’ recommendation and the visit to KITO with the DemoVan. The control system could not be used for construction reasons. This was then customised by Kranservice Essers GmbH in cooperation with KITO Customer Service. Mr Essers is convinced: “KITO is also a competent partner here.” The KITO ER2 immediately made a very robust and stable impression on Mr Höh and is exactly the right solution for their application. “We have been using the KITO ER2 units since 2020. It started with one hoist, and now six units – with another ER2 in reserve – are in use in the tempering plants to operate the material hoists. The chain hoists are used to lift so-called furnace grates filled with material. From there, the furnace grates are transported to the tempering plants. The cycle time here is every seven minutes.” An important point and a decision-making aid is the higher FEM rating of the KITO ER2 Electric Chain Hoists.

“It makes my team’s and my daily work easier and we can take care of other things that come up in the daily operation.”

Mr Höh has been convinced of the quality, the performance, the price-performance ratio of the long service life and the associated higher productivity since he first bought a KITO ER2 Electric Chain Hoist. “Everything is simply right here. During the conversation with Mr. Essers and Mr. Klar, I asked if there was a possibility to exchange the hook. It should be avoided that the load can move out of the hook. KITO has a solution for this too: the option of the safety load hook. In cooperation with Kranservice Essers, we feel we are in very good hands.” For Mr Höh, working with the KITO ER2 is characterised by its reliability: “We don’t need to beat about the bush. The reliability of the ER2 chain hoists is the be-all and end-all for me and the drive to continue working with Essers and KITO.”

“Competent partners for quick problem solving.”

We at Kito Europe GmbH would like to thank Mr Höh and Mr Essers very much for this interview. We are fully aware that this cannot be taken for granted, that it takes time and that daily tasks have to be left behind for a short time. We are proud of such good feedback and look forward to carrying out further projects with Kranservice Essers GmbH and Bharat Forge CDP GmbH. Mr Höh can only recommend the cooperation with KITO and the KITO sales partner Kranservice Essers: “Competent partners for quick problem solving”. “For Kranservice Essers, too, this was naturally a jump into the deep end. Do the KITO ER2 chain hoists meet the requirements? I can only agree with the words of Mr Höh. We look forward to future joint projects with Bharat Forge CDP and KITO.”

Within the interview, Mr Höh, Essers and Klar exchanged further views. Mr Klar informed that Kito Europe GmbH now also offers wire rope hoists. When the remaining service life of the next crane system has expired or the repair costs are too high, it is quite possible to imagine obtaining offers for the new wire rope hoist, the KITO RX Electric Wire Rope Hoist, via Kranservice Essers GmbH.