It’s simple – the highest priority when selecting overhead lifting equipment in food processing is to avoid contamination of the food. Naturally, it makes sense to use closed or covered food vessels, or processing lines. But it also makes sense to minimize the presence of contaminants anywhere in the general area where food is handled, stored or processed. For hoist, the most important contaminant to remove from the environment is lubricants made from petroleum products.

Common applications

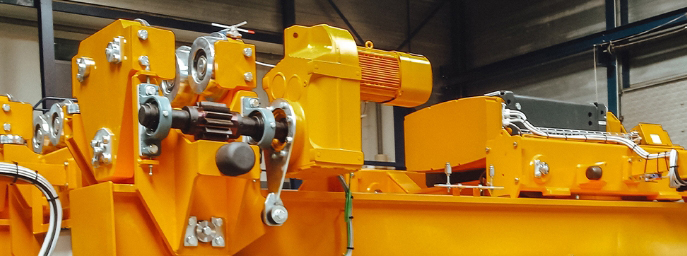

The variety of food processing applications is very wide: fish/seafood processing, bakeries, big bag handling for metering and mixing grains, and hotel kitchens are common, As well, secondary applications include lifting equipment used for maintenance of ovens, mixing machines, and packaging machines.

Regulations

Regulations vary widely from country to country, so consult your local or regional governmental agency for the final word on applicable regulations. But generally, it is up to the food manufacturer to insure his end products meet all regulatory requirements. In other words, the environment in which he operates is not clearly defined – but the contents of the products he produces are!

Factors to consider

Start by selecting hoisting products designed especially for food handling. If the product is not designed for food areas, it almost always contains oil and grease based lubricants that should not be introduced into foods. If these lubricants are found in food stuffs in high enough concentrations, the end product will likely fail regulatory inspection.

Ask the hoist manufacturer to provide a Certificate of Conformance in type 2.1 or type 3.1 according to EN10204.

Any oils or greases found in gearboxes, bearings, chains, or other moving parts must not be present, and instead any lubricants should be NSF certified.

This manufacturer documentation protects the food processor, as well as showing his commitment to cleanliness when third party food products, or food processing area inspections occur.

Another consideration is wash down of equipment, as corrosion in the processing area should always be avoided. Stainless steel components are practical in some cases, but can also be quite expensive. Very effective and reasonable prices alternatives include nickel plated components, especially for load chain.

Paints used to protect the hoist body may be OK as is, providing the manufacturer guarantees there is NO lead present in the paint, or used in the processing of the paint or hoist. Ask your hoist manufacturer to state this in writing! In some cases, white epoxy paint may be requested, but this is generally the result of the food processor’s wish to be consistent with the other equipment in his area. However, in some cases he may wish for this option when the main hoist body is steel based (for aluminum body hoists, this option seems redundant).

Determining a manually operated hoist compared to an electric hoist is a basic specification unrelated to the food processing requirement application itself. Ask the manufacturer for recommendations if this decision is not clear.

After Installation

Like any hoist, proper inspection and maintenance is mandatory. But beyond the basics for any hoist inspection, it is critical for both safety and cleanliness to check daily and make sure the hoist does not leak oil or have any unsafe electrical connections. Especially in food processing where water and steam are common, worker safety must be protected above all other.

For questions and further information, please contact the following e-mail address: marketing@kito.net