Maximum performance at a depth of 800 metres!

KITO ER2 electric chain hoists build a new bunker in a rock salt plant

In Germany, rock salt and potash salt are extracted from salt mines. High-quality salts are important for the everyday life throughout Europe and are used in many areas. Salt is used as fertilizer and nutrient in sustainable agriculture, it is a raw material for chemical processes, a component of industrial production chains, it is used in pharmaceutical substances, in water processing, as a de-icing agent in winter and finally, as a foodstuff, salt adds the right flavour to every meal. For so many different applications, salt needs to be extracted on a long-term and regular basis.

Smooth operations with underground cavities

One of the most important salt mines in Germany extracts salt from a salt pan discovered by chance. At depths of 500 to 1,000 meters, more than one million tons of salt are mined each year by dissolving it through blasting and then transporting it away via belt conveyors. To ensure a seamless flow of material without disruptions when it is transported to the surface, excess salt parts and backfill are temporarily stored in underground bunkers. The bunkers are an important buffer option for smooth operations and transportations. In this salt mine, they are created with the help of KITO ER2 electric chain hoists.

Easy load handling under extreme conditions

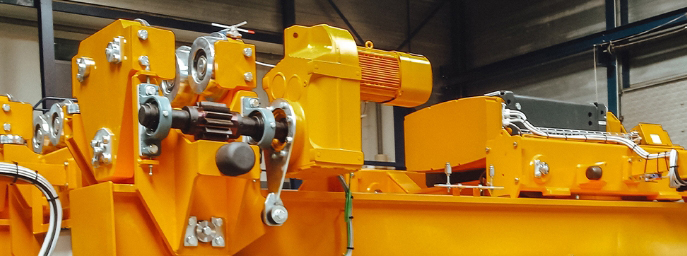

The robust KITO ER2 is a powerful and precise hoist for extreme operating conditions and fits perfectly for assembly work at a depth of 800 meters. The new bunker was installed below an existing mine. Heavy components and equipment had to be lowered safely from the starting point. KITO premium partner SEILTEC recommended the KITO ER2 for the application because it covers the required power supply of 500 volts as well as guarantees safe and efficient work in the long term. Like all KITO products, ER2 electric chain hoists are designed for permanent use. Underground temperatures of 35 degrees or more, salty air and low humidity don’t mind the tools. The chain hoists remain corrosion-resistant due to their aluminium housing (die-cast) and the powder coating. All internal components (including the electromagnetic brake, gearbox, frequency inverter and friction clutch) are not affected by the harsh conditions as well. Last but not least, the electroless nickel-plated load chain, securely placed in the steel chain container, guarantees a continuous flow. The KITO load chain withstands all external influences and is more resistant than conventional load chains.

For the assembly work in the salt mine, the hoists are equipped with a load capacity of 5 tons and 7.5 tons and a lifting height of 30 meters. Installed to a straight and a curved crane track, they ensure smooth lifting and precise placement of the load downwards the passage to the new bunker, with virtually no load swing!

The plant construction was done by the German company Heinz Wegwart + Partner.