The manufacturing of thin chemical products – like dishwasher tabs or washing machine tabs – needs demanding handling solutions. KITO EUROPE cooperates with many high-level plant builders, who create complete systems for chemical companies as in this case ATIK ANLAGENTECHNIK based in Buchholz, Germany. When you are searching for an electric chain hoist for this kind of mass production, KITO ER2 is often the first choice. Many automated systems cannot operate without the use of efficient lifting devices.

KITO ER2 is often used in the chemical industry for handling of “big bags” – large containers which carry bulk materials. The filling and emptying processes of the large bags are essential, because full-automated systems only work smoothly as soon as each sub-process is planned. The perfect handling of the big bags lies in the filling of the exact amount and emptying the bag down to the last detail at the right place. Sometimes, the bags have to be lifted over 10 meters and to be transported safely over the modern systems. This requires both power and precision.

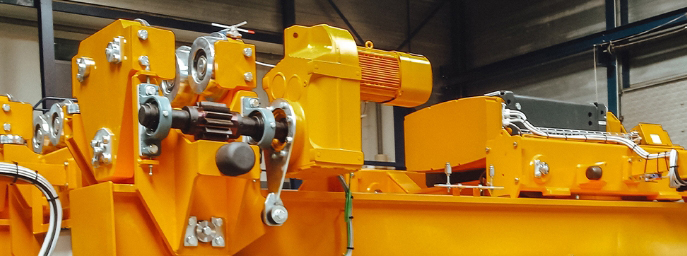

The KITO ER2 electric chain hoist with motor trolley represents such power and precision. That’s why it is often used for big bag handling. In terms of power, the load capacity is up to 1,250 kg at this project. But the ER2 can be configurated with higher load capacities, too. Precision is ensured by frequency inverters – at the hoist motor for lifting and lowering processes and in the power-driven trolley for cross-travel.

Even the official expert was excited when seeing the hoist operating at a recent customer: When he saw the radio remote-controlled KITO ER2 during the load test, he noticed that it does not slip behind at all. He never saw anything like this before!