Pipe bursts, collapses, cracks or root ingrowth: underground damages annoy local residents and companies – especially when the rehabilitation works involve high costs and a lot of time. To eliminate the problem and implement rehabilitation measures of the urban infrastructure efficiently, ProKASRO offers holistic solutions. Their progressive pipe rehabilitation works trenchless, without traffic obstructions and noise pollution. Sophisticated rehabilitation robots are safely lowered from vehicles into the maintenance shafts using KITO ED electric chain hoists – an advantage saving time and effort.

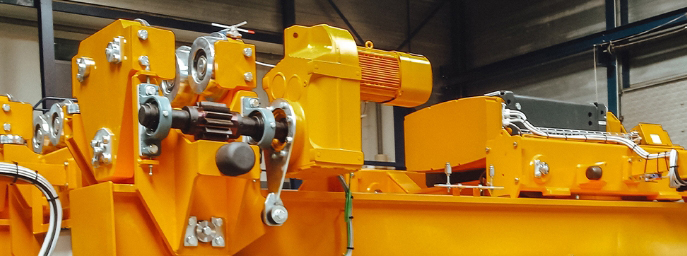

Malfunctions of the canal system do not only have effects on our everyday life in terms of hygiene, but do also mean horrendous costs and an enormous expenditure of time. Companies like ProKASRO produce devices which can bring sewer systems back into excellent condition. Instead of laying new pipes, ProKASRO works with progressive pipe rehabilitation robotics. This also includes equipping rehabilitation vehicles and upgrading used vehicles.

Beispiel für Zitatdarstellung Lorem Ipsum Dolar et sol sed amen dolor sit

Autor Name

Clean sewer systems thanks to highly evolved robots

Each vehicle is equipped with a rehabilitation robot and tools for the respective task. But how does the exclusive technology get to its workplace? This cannot be done by a single worker and two people do not work precisely enough. To lower the robots from the vehicles into the sewer system safely, ProKASRO was looking for reliable, light and flat lifting equipment with a load capacity of up to 100 kg. KITO EUROPE was the one who provided them with the best solution.

Ultra-flat and compact KITO ED electric chain hoist

Every year, up to 30 KITO ED electric chain hoists are installed into ProKASRO pipe rehabilitation vehicles. Thanks to its low dead weight and flat design, the KITO ED can be easily installed onto the crane beam in the vehicle. The lightweight aluminum gearbox of the KITO ED is extremely weatherproof and corrosion resistant. Thus, the crane beam can be moved out the vehicle at any weather condition to let the robot down the sewer system – even when it is rainy or windy.

At ProKASRO, KITO ED electric chain hoists are used with 2 different lifting speeds (7.7/3.0 m/min), a load capacity of up to 180 kg and a 10 m load chain.

As all KITO products, ED electric chain hoists guarantee ultimate safety. The load chain is secured by mechanic high-performance brakes . The integrated friction clutch provides additional security for the rehabilitation robots.

KITO ED electric chain hoist: sustainable, high-quality, reliable

Rémi Apfel from the ProKASRO sales team confirms the reliability of the KITO ED in daily use: “Until now, the chain hoists had no defects. That is more than satisfactory, because even a small defect would cause high costs for saving the rehabilitation robot. Our purchasing department is also impressed of the good quality. Even though KITO products are positioned in the upper price segment, they are easy to get, low-maintenance and efficient. This sustainability and the economic benefit are a great advantage for us!”