Germany’s foundries stand for challenging casting techniques and highest quality. But even these traditional companies always have to act with a view towards the future. One of Germany’s leading foundries has specialized in the production of iron castings and wants to reach a competitive advantage in the future through products with technological advances. This can only be achieved with first-class end products for construction machinery, mechanical engineering, the car and commercial vehicle industry, which are manufactured in state-of-the-art production facilities. And with KITO EUROPE as reliable partner for lifting hoists, which are used for regular maintenance works. KITO products, such as the powerful LB lever hoist, the compact KITO LX or the mini manual chain hoist KITO CX are a safe solution and ensure smooth processes in daily work.

More than old iron!

Germany’s foundries are essential partners for the automotive and mechanical engineering industry, for manufacturing agricultural and construction machines, for the railway industry and much more. Their success is based on years of experience, developing custom-fit moulded cast parts and producing always on schedule. Thereby, product quality of iron cast parts strongly depends on the production technique behind it. Future-oriented companies use modern, fully-automatic moulding lines or robot-supported deburring stations in order to produce high-quality components.

An important step towards the future

The extension of production with modern machines requires a great extent of finesse and knowledge of possible customer demands. Whether the components need to meet specific thermic, metallurgical or mechanic requirements – every demand must be fulfilled with highest ambition. This can only be achieved with innovative production facilities. It is also great to be equipped with high-tech machines, because you can handle more orders and you can react to changing market environments quickly. Both with a high level of quality.

Holistic solutions

A plant working with modern production machines always needs modern methods of maintenance, too. That’s why one of the leading foundries from Germany chose products from KITO EUROPE for all maintenance tasks. Klein Seil- und Hebetechnik GmbH did the perfect consulting and acted as distributor for the Japanese hoists.

“When I got the inquiry, the solution was immediately clear to me. KITO hoists impress with fine adjustment and first-class gearboxes. They are just perfect for installing and maintaining different machine parts”, says Steffen Büdenbender, technical consultant at Klein Seil- und Hebetechnik GmbH.

Everything made of one cast!

The foundry was quickly and easily equipped with the lifting equipment in order to make the maintenance of the production facilities as easy as possible. “It’s clear that maintenance and repair processes can slow down daily operation – this is particularly annoying when you are handling a major order. But I know how safe and easy it is to work with KITO chain hoists, so I have only recommended these products.”, says Steffen Büdenbender.

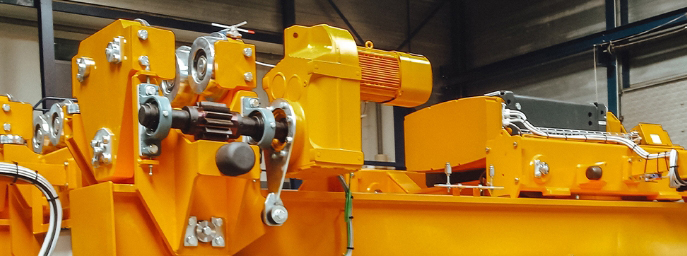

After the workers of the foundry have tried the KITO products for the first time, they were convinced by the quality. Now, the entire foundry uses exclusively products of the Japanese high-tech manufacturer and all maintenance work is done with the yellow hoists.

Challenging work environment? Perfect!

KITO products are durable and withstand the tough conditions within the foundry. Small spaces, a dusty surrounding and high temperatures are not a problem for the tools. The KITO LB lever hoist is used for heavy pull, lifting, and clamping operations. It comes with a fine-toothed precision gearbox. And by using double reduction gearing and a patented induction hardening process on load bearing parts, the hoists weight and size is reduced while overall strength is improved compared to other products. Ultra-light and compact KITO CX mini hoist makes it easy to lift, pull and position small loads. The KITO CF manual hoist is particularly designed for aggressive and rough environments such as those in foundries – it has an extremely robust closed Aluminium die-cast. Just like all KITO hoists it features a long service life and reliability while processing maintenance work, repairs, and reconstruction tasks. For the foundry workers this means significant time and cost savings, an increase in productivity and a considerably smaller workload.

Efficient quality management – always a step ahead

The foundry promises its customers holistic product solutions at every level. This includes not only the planning of the components, professional production and ultimately the on-time delivery. Product quality always starts at thought-out and flawlessly-functioning production plants.

Steffen Büdenbender from Klein Seil- und Hebetechnik GmbH is proud: “The foundry is obliged to deliver high-quality products to its customers, which are crucial for the success of the end products. We see ourselves as part of this value chain. By providing KITO products for maintenance works, we help the foundry and its customers to achieve their strategic and operational goals. And to act future-oriented at any time.”