Europe’s most modern tractor plant includes ERIKKILA light crane systems and electric chain hoists from KITO

The DEUTZ-FAHR LAND in Lauingen, Germany, is not an amusement park, but one of the world’s most innovative tractor plants. DEUTZ-FAHR is a reliable “Made in Germany” tractor brand, who set a new industry standard with its 150,000 m2 plant (40,000 m² covered). One single crane partner managed the major project in terms of planning and equipping all assembly stations. To offer the customer and each employee huge advantages in the assembly of the green tractors, customized ERIKKILA light crane systems and KITO hoists were installed in the factory.

Offense in the agricultural industry: 90 million Euros for a new production facility

DEUTZ-FAHR has established in the agricultural engineering as a manufacturer of innovative and productive tractors and combines for over 90 years. The products – especially the tractors – offer easier work, maximum productivity and profitability for the farmers. In order to remain its top level and to face the future, the company decided to invest a total of 90 million Euros in the construction of Europe’s most modern tractor plant called DEUTZ-FAHR LAND.

New standards in the tractor production and familiar partnerships

DEUTZ-FAHR LAND celebrated its opening in 2017 in Lauingen (Bavaria, Germany) after almost three years of planning and construction. The plant manufactures series of high-performance tractors as of 130 hp for the global market. 40 tractors of 16 different series are produced every day, which requires a thoughtout concept and state-of-the-art technologies. Carl Stahl was responsible for the crane equipment of the whole plant, who in turn consulted the KITO Group to find the best lifting solutions. Together, more than 60 customized load-carrying devices were developed for the tractor plant. There were test loops again and again to match the ERIKKILA light crane systems and KITO electric chain hoists to the manufacturing processes. A lot of new technical solutions were applied, which did not exist in the agricultural industry before. So, DEUTZ-FAHR not only stands out from the competition, the company rather secures a technological leading position.

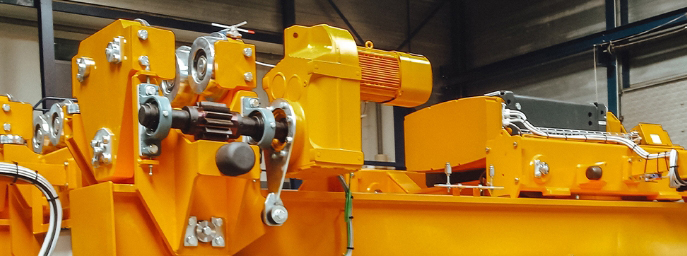

ERIKKILA cranes made of aluminum and steel

To guarantee an efficient tractor production, the plant was equipped with an intelligent infrastructure of ERIKKILA light crane systems. The PROSYSTEM series workplace cranes increase productivity due to short throughput and waiting times. A total of 15 lightweight aluminum crane systems with internal conductor rail for power supply were installed on the ceiling above the pre-assembly – ensuring a wireless, safe and clear working environment. The power supply to conductor lines located in the profiles was based in the modular end plate.

Another 45 light crane systems are placed above the tractor conveyor belt where the runway is over 400 meters long. The ERIKKILA aluminum profiles are made of high-quality anodized aluminum and have a maximum load capacity of 1,000 kg. The trolleys have a steel housing as well as smooth-running and almost silent rollers. Due to the self-centering function, load swing is minimized.

ERIKKILA’s advantage: The system has the best weightcarrying capacity ratio between light weight and long suspension distances. And the intelligent identification of the individual aluminum profile sizes makes it easy to identify the components during assembly. In addition to the aluminum profiles, 8 light crane systems made of steel profiles with a load capacity of 1,500 kg were installed. The power supply also works with a conductor rail located in the profile, preventing cable loops hanging down in the workplace. ERIKKILA light crane systems with steel profiles can be used for maximum load capacities of 2,000 kg.

Logical addition: KITO electric chain hoists

The smooth-running ERIKKILA workstation cranes in the tractor production have been extended with 50 KITO electric chain hoists (KITO ER2 and KITO CDER2 with cylinder control), which can be positioned precisely in all directions. During the assembly of the tractors, the hoists stay safely in the selected position helping the employees to pick up the load or to mount the components precisely.

KITO electric chain hoists are of high quality and reliability. KITO is the only manufacturer in the world who nickel-plates its load chains, which guarantees low wear and high strength. In addition, the load chain is protected against corrosion. The electric chain hoists use optional frequency converters for gently lifting or lowering the loads. This allows precise positioning of the components, especially during assembly. Among all this, the carbon friction clutch protects against overload. The technical highlights of the tractor plant are the KITO hoists at the installation of the bonnets which work with vacuum technology.

The technical highlights of the tractor plant are the KITO hoists at the installation of the bonnets which work with vacuum technology. The vacuum technology is fixed at the KITO ER2 electric chain hoist and transports the bonnet through a low profile on a curved path to the perfect position at the tractor.

A more modern equipped tractor plant can’t be found in Europe!

DEUTZ-FAHR and Carl Stahl have chosen the perfect partners in ERIKKILA and KITO EUROPE. KITO EUROPE acquired ERIKKILA at a later stage and is now able to offer comprehensive light crane systems and industrial workstation systems. The KITO hoists complete the ERIKKILA cranes in terms of quality, safety and ease of operation. “Everything from one source” is a big advantage for every user.