Customised lifting solutions for a surface coating company

For over 30 years, the German company Hentschel Harteloxal has operated plants for anodising metals out of aluminium, chrome or stainless steel for further usage in mechanical engineering, aviation and other industries. Throughout the years, the production area has expanded to two large halls equipped with different transport methods to move the metal parts and sink them into the coating basins. KITO EUROPE and partner Carl Stahl optimised this operation and designed an efficient crane system.

Hentschel Harteloxal has two production halls for metal finishing. Both halls contain electroplating and plunge basins with a liquid coating to provide high-quality corrosion or wear protection for metal components. Before the redesign, metals were often dipped-in and lifted out of the basins by hand. So, there was a clear challenge for KITO EUROPE to meet employee safety and comfort: an efficient crane system had to be installed to precisely sink the components into the basins. There had to be as much free space as possible on the floor. On the ceiling, the space for suspensions was also limited, as the challenge was to fit the crane among the sprinkler lines and an existing crane while still fulfilling the desired operation.

Complex task: a large working area, little scope at the ceiling

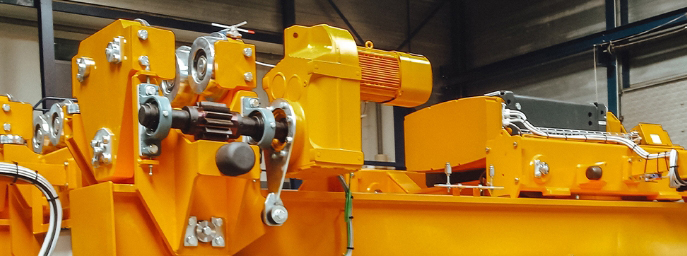

KITO partner Carl Stahl recommended combining a KITO ERIKKILA Prosystem light crane solution with a KITO EQ Electric Chain Hoist for maximum benefit. The KITO ERIKKILA crane tracks were chosen with different bridge spans and asymmetrical overhangs to fit perfectly into the production hall and under the existing crane system.

KITO EQ: An efficient and powerful hoist for any production

The KITO EQ makes the handling of the metal parts much more comfortable. Thanks to the standard integrated high-quality frequency inverter, the hoist runs smoothly, the metals can be dipped precisely into the coating basins, and they can be easily positioned in the drying area afterwards. Hentschel Harteloxal’s KITO EQ Electric Chain Hoist out of die-cast aluminium has a load capacity of up to 250 kg and a threemeter nickel-plated load chain. Other safety features of the standard version are the electromagnetic pullrotor brake, electronic thermal motor protection and overload protection.

The update of the production halls is a perfect finish for the metal finisher: no other lifting devices are needed, and all transportation elements on the ground could be removed. The flawless interaction between the KITO ERIKKILA Prosystem light crane and the KITO EQ Electric Chain Hoist results in smooth operation and maximum workplace safety.