A KITO ER2 electric chain hoist is combined with a vacuum lifter to upgrade the production of traffic signs

In Germany, there are over 500 traffic signs but only a few companies have a manufacturing license for them. The criteria for the appearance and the condition of the signs are clearly defined, and the construction follows a strict quality management. Every day, signs are produced for new roads and road improvements or to replace dilapidated, destroyed and unfunctional signs. One producer is a traffic engineering company that is specialized in the production of vertical traffic signs, tourist signage, road names and cycle path signs.

Optimal handling in sign production

For the optimal workflow in traffic sign production, various steps must be done at different workplaces. At first, the traffic sign image is printed on a retroreflective foil. Depending on the size of the traffic sign (up to more than 50 sqm!), one or more foil sheets are needed. After that, the foil is cut to size and glued to a metal shield – either separately or in strips if it is a larger sign. At the end, all sign parts are set together and screwed from behind. As each sign must be clearly legible, no errors may occur during this process. All signs must be perfectly combined from the front and the back.

There are different workstations for each production step in the traffic engineering company. The challenge: every (large) sign must be turned around and change position safely for processing. The company’s individual solution for this is connecting several lifting elements:

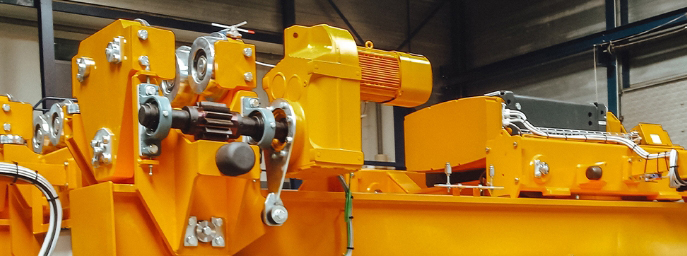

a KITO ER2 electric chain hoist carries a vacuum lifting device – and both are attached to a double-girder crane from KITO ERIKKILA.

All-round movement and 180° rotation due to the combination of KITO ER2 and a vacuum lifter

Vacuum lifting devices, like the VacuMaster Comfort from J.Schmalz GmbH, can rotate heavy and large loads through more than 180°. This ensures that the signs can be turned around in the production process. For the final assembly, Hans – Hebetechnik + Metallbau GmbH has developed a special solution. The KITO ER2 electric chain hoist is combined with the vacuum lifting device, both are carried by an KITO ERIKKILA crane. By this, the vacuum lifting device can not only be used at one station to pick up and rotate the traffic signs, it can also position the signs at different workplaces precisely after they have been picked up.

The KITO ER2 is the best choice for a smooth movement of the almost 150 kg vacuum lifting device without load swing. The two devices are attached safely at the 33 meters KITO ERIKKILA crane track and ensure smooth transport of the signs. The die-cast aluminium body of the electric chain hoist not only ensures a long service life of the hoist and thus of the entire system, it is also a safe storage of the high technology inside (including electromagnetic brake, frequency inverter and friction clutch).

What’s innovative: for the crane and trolley movement as well as for the lifting and slewing motions, the KITO ER2 electric chain hoist is not controlled via its own control system, but directly via the panel of the vacuum lifting device. The two devices were connected. Both the KITO ER2 and the Schmalz VacuMaster Comfort get their energy supply from an external electronic trolley.