KITO EUROPE equips SCS Werkzeug- & Vorrichtungsbau (tool & fixture construction) with a new crane system and thereby supports the smooth production processes

Currently, all electronic-manufacturing companies face the same challenges: more and more complex components are required. The numbers of different components of an assembly increases. And the time frames are so short that they can hardly be fulfilled. The industry must therefore rely on medium-sized suppliers, which manufacture devices with high precision and deliver them in a targeted manner. The company SCS GmbH Werkzeug- & Vorrichtungsbau is such a reliable pillar. The company from Viersen, Germany, develops and supplies high-quality equipment both for electronic manufacturing and other manufacturing processes. A fully installed KITO jib crane with a KITO EQ electric chain hoist ensures a smooth production process, because it positions the components safely and precisely.

Complexity and skill

These two constants are vital, if you want to survive in the business of development and production of resources. Because only those who are able to think and plan in a complex way are ready for the production of complex components. The company SCS GmbH Werkzeug- & Vorrichtbau from Viersen, Germany, is grounded in this market for tools, fixtures and special machines for more than a quarter of a century. The medium-sized company offers tool manufacturing as well as the development and construction of fixtures for electronic manufacturing. It doesn’t matter whether it is a single component or a serial production. Every day, the company executes the serial production of the most complex components from the design stage to the finished product.

Individual problems are solved with custom-made fixtures

For SCS, it is important to know about all customer requirements. “With the development of custom-made fixtures and tools, SCS offers a variety of solutions for the individual problems in the field of electronic manufacturing”, says Managing Director Hermann Claßen. Joachim Schmäck, also Managing Director, adds: “In addition to a smooth process at all stages of the production process, our special goal is to find a cost-efficient solution for the tasks and for our customers.” These high targets for electronic manufacturing specialists require a clear structure and well-organised production facilities. State-of-the-art production machines as well as motivated and well-trained personnel stand behind the team and ensure the high quality requirements of the company.

KITO products are part of the team

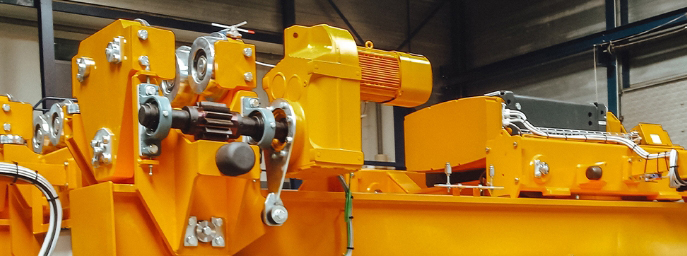

SCS focuses on two production areas: the sawing machines and the CNC (Computerized Numerical Control) machines. The assembly of these machines must be fast, simple and precise – for the employees it is hardly possible to do this by hand. In addition, the components need a certain retention period in the machine. In order to provide workers with physical relief and ensure safety during production, a column-mounted slewing crane with a KITO EQ electric chain hoist was installed on the CNC machine tools. The KITO electric chain hoist is small, compact and easy to use. Therefore, the sometimes heavy components can be precisely fed into and removed from the CNC machine. Thanks to the large radius of the slewing crane, two CNC machines are efficiently served by the chain hoist.

Precision material loading

The electric chain hoist KITO EQ is robustly and solidly built and due to its inverter it guarantees a precise positioning of the load and an extremely high running stability. Furthermore, it is equipped with an upper and lower limit switch, thermal protection and an operating hours and load cycle counter. The hoist is designed to meet transport tasks and to fulfil the requirements in every respect.

Because of its easy handling, the KITO EQ electric chain hoist is used in almost all industries, eg. in the paper industry, in steel companies, in wind power plants and also in medium-sized productions, where it is used for the handling of heavy parts, sheet metal, assemblies and welding workstations. The KITO EQ stands out by its versatile product options. Lifting capacities from 125 kg up to 1,000 kg cover a high range of applications, the suspension variety ranges from the hanging version to the push trolley, the geared type trolley and the electric trolley.

Production around the clock

The KITO EQ is also an critical part of the manufacturing processes at SCS GmbH Werkzeug- & Vorrichtungsbau. “The electric chain hoist is an integral part of our organised operations”, confirms a staff member in the production hall. “We can easily pick up the individual parts with the belt and position them exactly in front of the machine. This way the work never comes to a halt.”

SCS has a large and constantly growing range of systems and fixtures for the electronics industry. More than 50,000 blanks are processed annually to produce precision parts for the electronics industry – the consistently high quality is, among other things, guaranteed by the use of KITO hoists.

Press contact: Minna Freyberg, marketing@kito.net