KITO EUROPE hoists are essential tools at frischli dairy

The food industry is very selective in choosing hoists. Due to the increasing customer demand more and more food is produced. The facilities hardly ever stand still and need tools that can keep up with the constant production. In addition, the food industry has the highest quality standards in terms of safety and cleanliness, because the equipment of the production facilities should be as safe and clean as the final products itself. Several electric chain hoists, hand chain blocks and lever hoists are in use at the headquarters of frischli dairy in Rehburg/Loccum, Germany, for the production of UHT milk, milk powder and cream.

Spoilt for quality

Germany has the highest priorities when it comes to food processing. Consumers are usually unaware of all the processes happening behind good quality. Not only the food needs to be selected, tested and handled with care. There are strict regulations for the tools which are allowed in the production, too.

Since more than 110 years, frischli is one of the most modern and high performance dairies in Germany, serving retail and professional customers in Germany and abroad. With a turnover of 500 million Euros, frischli is the leading specialist for long-lasting, uncooled dairy products from fresh milk and milk powder to cream and dessert specialties. The company has committed itself and each of its 1,200 farmers to work with the highest standards in quality. This promise also includes the right equipment in the processing facilities.

Delivering the best every day

“Due to our state-of-the-art processing and filling technology, we are in a position to manufacture basic products very efficiently at an excellent quality, and in large quantities.”, says Detlev Curt, Group Leader Mechanics at frischli. His challenge was difficult: “About 10 years ago, we were looking for a lifting equipment partner to supply us with a comprehensive ‘carefree package’. We searched tools for common applications in the food industry, such as “big bag” handling and maintenance. Just like the frischli products, the hoists should be of high quality.”

The contact to KITO was established via premium partner Sander Hebe- und Sicherheitstechnik GmbH.

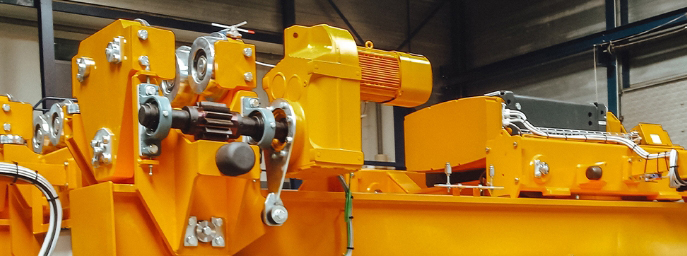

frischli & KITO EUROPE = safety for employees and food products

KITO ER2 electric chain hoist has all the features frischli was searching for. The three-phased electric chain hoist is available with a load capacity from 125 kg to 20 t – it can have a top hook or connector, comes with plain, geared or motorized trolley and has all the abilities to handle “big bags” and other loads easily within the food processing. At frischli, the KITO CB hand chain block supports at maintenance works. It is a compact “easy-to-use” hoist, has a shock-resistant double gear casing, a double-pawl spring system, a robust mechanical break and a nickel-plated load chain like every other KITO product.

“The machines at our facilities hardly ever stand still. All hoists should withstand the permanent loads for as long as possible and at the same time be easy to use. Unnecessary halts and pauses delay our processes, so do devices that often fail or are difficult to operate, “says the Group Leader.

Regular plant maintenance and check-ups

frischli has the perfect know-how to develop food products that are tailor-made for professional food service, industry processing and retail customers and consumers. KITO EUROPE supports the frischli business with professional lifting solutions. Together, strict audits and regular controls are executed successfully.