KITO SHER2M electric chain hoist lifts pumps in a water-recycling plant

Efficient wastewater treatment is a demanding task. It takes years to design and build a recycling plant to the highest standards. The plants are an important part of the drinking water production and must always comply with the latest environmental regulations.

Modern wastewater treatment in Finland

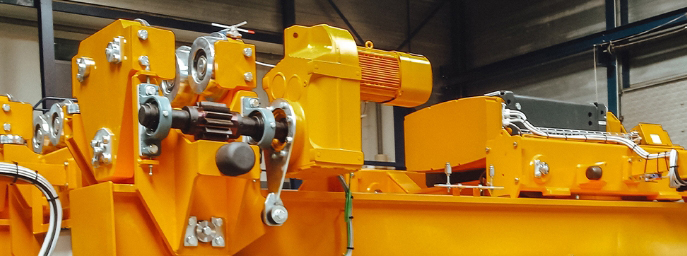

The Swedish construction group Skanska is a pioneer in the development and implementation of waterrecycling plants and operates mainly in North America and Northern Europe. Recently Skanska completed a project in Finland. Even though the Finnish plant was designed with appropriate ceiling height, you will find areas where lifting processes have to be done with high loads and little space. A real challenge is the regular maintenance work when the huge water pumps have to be lifted. The area above the pumps is limited, but KITO long term partner Finmotor OY has installed a strong solution there for Skanska: a KITO SHER2M electric chain hoist with low headroom mounted on a monorail directly above the water pumps. Thus, the small space above the pumps is used completely, the water pumps can be lifted safely, and maintenance work can be carried out optimally.

Overcoming large lifting heights

Little space and low ceilings are no barrier for the KITO SHER2M electric chain hoist. The ‘Short Headroom ER2 Motorized Trolly Type’ is literally the short design of the robust KITO ER2 electric chain hoist. For the lifting processes in the Finnish wastewater treatment plant, Finmotor OY has chosen a model with a load capacity of up to 2,000 kg and a lifting height of 12 m, while the electric chain hoist itself has a headroom of only 435 mm. With built-in technical features such as a frequency inverter for precise positioning and an electromagnetic brake, the chain hoist masters all maintenance tasks safely and without much effort.

The load chain is the real strength of the hoist

The compressed design of KITO SHER2M is possible because of the special chain guide. To lift the load directly under the carrier, it is taken advantage of every centimetre. However, not only the guidance of the load chain, but also the chain itself is perfect for load handling under special conditions. KITO is the only manufacturer in the world that nickel-plates its load chain and uses this standard for all hoists. The load chain resists hydrogen embrittlement and is more corrosion resistant than conventional load chains. This is a unique advantage, not only when used in water treatment plants. The KITO SHER2M is the answer when you need power in every centimetre.